But not by me. This red plastic box was in a suitcase of vintage patterns and assorted sewing stuff which I bought at an auction ages ago (and it made a fair contribution to the overall weight of the suitcase).

|

| Mystery box |

I looked inside, thought

"Ooh, interesting", and put it on a shelf in my workroom to investigate properly later. And there it has sat, for about 4 years, until it caught my eye during a recent tidy-up, and I decided that it really

was time to look at it properly.

The detail on the box lid, below the Singer logo, gives a hint of what's inside.

|

| Can you guess? |

It's an attachment for making buttonholes on a straight-stitch machine, such as my 66s and 99s (but also models such as 15, 128, 185 and 201). The box is cleverly designed to hold all the pieces securely, so there's no danger of anything getting lost.

|

| Everything neatly in place |

|

| This (important) piece actually screws into the box |

Tucked right at the bottom of the box was the receipt. I assume that of the three items bought from the Singer shop in Chester, this was the one which cost four pounds, 18 shillings and fourpence. Sadly, although the receipt clearly shows the purchase date as 20 Jan, it does not give the year.

|

| I wonder what else they bought? |

There is no year mentioned anywhere in the instructions, either. There is however a reference to the

"new "Featherweight" portable", so based on this I'm guessing at a date somewhere in the 1950s. This particular buttonhole attachment doesn't seem to have been sold in the States, so there's limited information about it online.

It's a complicated beast, as is apparent from the illustration and parts list (three pages long!) in the instruction manual.

|

| All the parts |

I love the fact that if a washer snapped or a spring broke, you could simply get a replacement part from Singer, rather than have to buy a whole new attachment. Mind you, that approach to sales may go some way to explaining why Singer eventually went bust!

|

| With the cover removed |

The attachment works by moving the fabric from side to side between stitches, so the machine's feed dogs have to be covered with the plate, which is screwed in place using the same holes as the

seam allowance marker.

|

| Feed cover plate in place |

The attachment has a fork which is positioned around the needle clamp, and the whole thing is screwed onto the presser foot bar. It's a bit of a challenge to do all this without bending the needle!

|

| Showing how the attachment is attached |

Unlike later models, which used drop-in templates to make different styles such as keyhole, this version can only make straight buttonholes. It is possible to alter the density and width of the stitches and the width of the centre gap, however. The buttonhole length can be between ⅜" and 1", and it's possible to extend it up to 1⅞" with manual intervention.

I tried doing some test buttonholes, with red thread on top and cream in the bobbin. The initial attempts were not a success.

|

| From 'very, very bad' to 'not much better' |

The underside looked even worse.

|

| This is the underside - there may be some tension issues! |

At this point I took the buttonhole attachment off, checked the tension with ordinary straight stitching, and made a few adjustments until I was entirely happy with it. Then I tried again (this time with yellow bobbin thread).

|

| The right side |

|

| The underside - at least it's mostly yellow |

It's obvious that there's still a lot of work to be done, but I think that it's mostly in improving the skills of the operator! The instruction manual for Olive, my mum's (now my)

1953 Singer 99, has the threading diagram annotated with little felt tip arrows which I added because 50 years ago I couldn't follow the instructions - now I could probably thread a 99 or a 66 in my sleep. So the fact that I can't make perfect buttonholes on my first attempt isn't too much of a worry.

I should add that I did all this on Tilda, my original 66 treadle. I thought that treadling for long enough to do a buttonhole would be exhausting, but it took far less effort than I expected, even going round it twice. The instructions stress the need to work slowly, so a treadle rather than an electric machine is probably ideal.

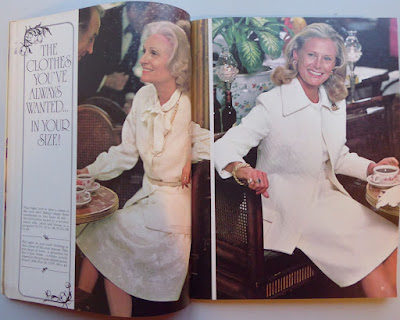

I've written many times on this blog about hand sewing and slow sewing, and if I only have a few buttonholes to do on a garment then I think that hand-sewn buttonholes would remain my first choice. However, I have a couple of shirtwaist patterns on my 'would like to make' list, and even I balk at the idea of that many buttonholes. So there's a good chance that machine buttonholes may be making an appearance in my wardrobe sometime.

|

| Lots of buttonholes - Hollywood 805, from 1942 |