The fabric was just labelled 'wool mix', with no indication of what was in the mix, and how much of it was wool. So, as I had decided to use fusible interfacing and I am in the 'use steam' camp, I thought that I had better check what effect said steam would have on said wool mix. I cut 15cm squares of fabric and interfacing, and fused away.

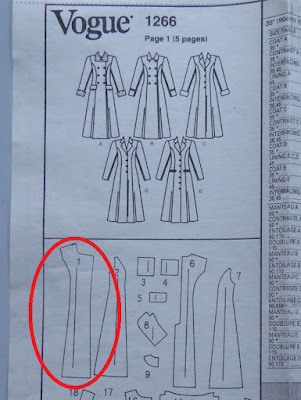

It was as well that I did so, as while the width of the square remained the same, there was a noticeable reduction in the length (along the grain of the fabric). This was a blow, as the pattern calls for the interfacing to be attached to the coat fronts rather than to the front facings, and by this time I had already cut the coat fronts out. Fortunately I hadn't yet cut out the facings, so they have had to be interfaced instead. I fused a large piece of interfacing to the remaining fabric, and cut the facings from the pre-shrunk piece.

|

| That's a lot of potential for shrinkage |

Then it was finally time to start sewing, which presented another dilemma. It's a sturdy fabric, and I really didn't want to risk putting it through my main sewing machine. My Jones dates from 1986, when machines were still mostly made of metal and fairly robust, but nonetheless, I feared for its motor.

So, I turned to my treadle. I bought this at the local auction two years ago, and somehow never blogged about it. I think that I was waiting until I could sew something on it, but then of course Things Happened.

|

| Tilda |

It's a Singer 66, made in 1933. The 66 model is almost exactly the same as the more common 99, just with a longer arm. As the model numbers suggest, the 66 was made first, and then the 99 was created as a smaller 'lightweight' version (note: the term is entirely relative, and probably wouldn't get past advertising standards today!).

The machine was in very good condition, and the only thing which appeared to be wrong with it was that the treadle belt was broken. I assumed that I would be able to get a replacement belt online, and I was right - I just didn't expect to be able to buy it from the Singer website! It's a testament to the brand that clearly there are enough antique and vintage Singer machines out there and still in use for Singer to consider it worth their while to sell spare parts on their UK website.

Although the machine appeared fairly clean and shiny on the outside, I got a bit of a shock when I took the endplate off. It looked as though something had nested in there - I genuinely expected a small creature to shoot out and scuttle off to a dark corner of my workroom!

|

| Ewww! |

Fluff gingerly removed with very long tweezers and new belt attached, I had a few attempts at treadling, and then stopped as other things took over. I certainly wasn't going to churn out sets of scrubs on a treadle machine! But for making a coat, it's ideal. For starters, the machine bed is flush with the rest of the table, and there's a large area to the side for resting the fabric.

|

| Large, flat, working area |

I'm always very fussy about not having drinks on my worktable in case of spillage, but Tilda's layout provides a handy but out-of-the-way place to put my mug of tea!

|

| Perfection (biscuits for illustration only)! |

On a more practical (but not more important) level, there's a lot of oomph behind that needle. It's a long time since I studied Higher physics, but I'm still vaguely aware that a large, heavy flywheel connected to a small driving wheel is going to generate a fair degree of force. Certainly, it glides through several layers of coating fabric with impressive ease.

I remember when I was a child trying, unsuccessfully, to operate my grandparents' neighbour's treadle machine. Courtesy of a few YouTube videos, I now know why I failed. I had my feet side by side, and simply wiggled my ankles. This seems the obvious method, but was never going to work. Ankle joints are fairly puny, and treadle mechanisms are heavy. What you need to do is have one foot in front of the other, and press down on each one in turn using the big muscles in your thighs. A bit like pedalling a bicycle, but up and down only. Getting the wheel, and therefore the feed dogs, to move in the right direction is still a work in progress, but I'm assured that it becomes second nature over time.

That's the treadle part, but I've also learned something really useful which applies to all of my vintage machines. None of them have the ⅛" gradations for seam allowances marked on the needle plate, so I have always had to work by eye, or put a bit of low-tack tape on the needle plate. No longer. A huge thank you to @Muchacha_Vintage for showing me how it's done, and what that mysterious bit of metal actually does.

|

| So that's what it's for! |

I love the fact that even though it's almost 50 years since Mum first sat me down in front of her Singer 99, I'm still learning something new!

Fascinating! I too have an old Singer treadle - 1950s. All the physics info you have included makes a great deal of sense. Thanks. I look forward to the next instalment!

ReplyDeleteThank you Kate. I love how well these old machines still work after a clean and an oil, because there's really not much to go wrong. Do you use your treadle?

DeleteDear Elaine,

DeleteSorry this reply is a bit late! I bought my 1950s treadle three or four years ago from a wonderful place near here https://www.helenhowestextiles.co.uk/ - she deals in vintage sewing machines and is a quilter. The treadle was fully reconditioned by Helen's lovely partner, who has sadly since died.

It works beautifully - but my skills and efficiency are somewhat cranky! I am currently working on a writing and sewing project, which I suppose is a form of research through living history!

Anyway enough of rambling!

All the best Kate

Dear Kate,

DeleteThanks for alerting me to Helen's website - the tension on my 1917 hand-crank needs some attention, so I may be on the look-out for parts. Meanwhile my treadling skills are getting better, although sadly, not consistently so!

Your project sounds interesting, I hope to hear more about it.

Elaine

Dear Elaine,

DeleteDefinitely Helen Howes is the place for spaares and parts and knowledge!

All best

Kate

Sewing and exercise at the same time!

ReplyDeleteExactly. You don't get a completed coat at the end of a peloton class!

DeleteI'm looking forward to your coat progress, but I must admit that my heart beat a bit faster when I read about/saw your Singer treadle! I learned how to sew on one! I don't recall the foot movement, but it did "glide". I moved away (literally) from the treadle and onto a Singer Featherweight. My sister and I can't figure out what happened to it, but I recently found one that I just got back from the repair shop, so I'm hoping for a "heavy duty" backup!

ReplyDeleteYes, you can't beat a large lump of cast iron when you need a machine with a bit of heft! My mum's machine had been a hand-crank, with a motor added later by my dad (in the days when putting electricity and metal objects in the hands of amateurs was perfectly acceptable) so this is my first real experience of a treadle, and I'm loving it!

DeleteAnother treadle user - woot!

ReplyDelete