I'm finding this project a real challenge, and not in a good way. Add in a whole load of Life Issues taking up a lot of time, and general January bleugh-ness, and I must admit I'm not exactly a happy camper right now. So if you don't fancy reading several paragraphs of whinging, I quite understand, and I'll see you next week!

On the plus side, it was lovely to see how last week's introduction to Tilda the Treadle really struck a chord - thank you so much for sharing your own treadle experiences. Practice is making, if not exactly perfect, then at least a great improvement in my treadling skills.

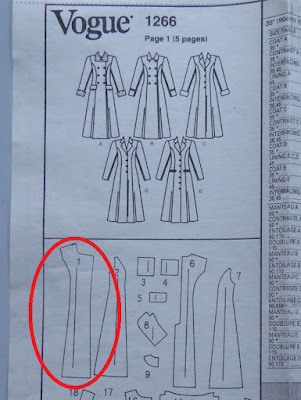

This project has made me aware of what small parameters I usually work within; both in terms of the materials I use, and what I make. Yes, I do a lot of sewing, but it's usually with mid-to-lightweight fabrics which press easily. Even something like New Look 6594, for all the challenges, workarounds and Very Rude Words which went into its construction, fitted into this range. Also, I make surprisingly few things with collars which have separate pattern pieces. The last coats I made, Butterick 5716 and Simplicity 4896, both had grown-on collars.

So, whinge number one. The coat fabric is fairly resistant to being pressed, and because of the shrinkage issue, I hesitate to use too much steam. As a result, I've taken to catching down all my seam allowances to keep the insides flat.

|

| Looks neat, but takes time |

I rarely tack/baste anything, being firmly in Team Lots-of-pins-and-hope-for-the-best. But because this fabric is so thick, the top layer tends to stretch out under the machine foot, especially on long seams. So all seams are now tacked, and I find I have to use stab rather than running stitch to keep the layers together properly. Which takes more time that I'm not used to expending.

Also, the whole thing is very heavy and hard to manipulate, even though it doesn't yet have sleeves! Tilda's large work surface is a boon, but it is still tricky to keep the entire garment from sliding to the floor.

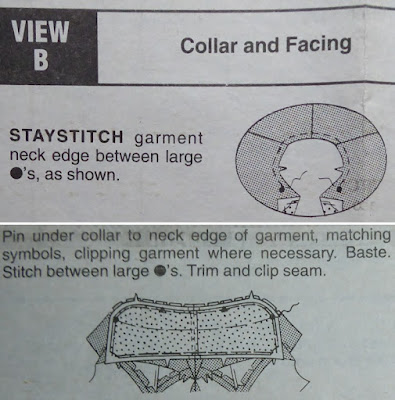

Finally (I did warn you there was a lot of whinging!) I'm just not used to tailoring methods. When collars do make an appearance in my projects, the construction tends to be: make the collar, sandwich said collar between facing and main garment, sew round from front to front, job done. With this pattern however, the back and fronts of the coat are sewn together at the shoulders, the neckline is stay-stitched, and the under collar is attached.

|

| Instructions |

This did at least produce something which looks a bit like a coat.

|

| Sort of |

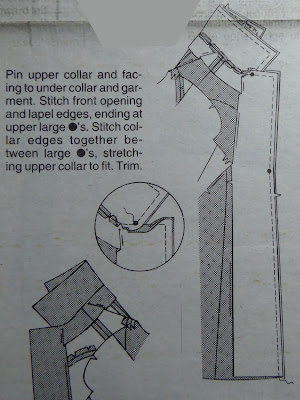

The process is repeated with the facings and the upper collar. And then, the two are sewn together in three stages - the fronts first, and then round the collar. I found it very fiddly.

|

| More instructions |

This is as far as I have got. Next comes a whole lot of pressing, trimming seam allowances, and yet more pressing, much of which is likely to have limited effect. I see a great deal of understitching in my future, and I'm not looking forward to it.

Thank you for coming to my TED Rant!